|

Size: 2188

Comment:

|

Size: 2233

Comment:

|

| Deletions are marked like this. | Additions are marked like this. |

| Line 19: | Line 19: |

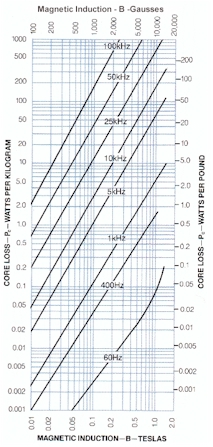

| || [[attachment:2605SA1_coreloss.jpg | {{attachment:2605SA1_coreloss.jpg}}]] || Core loss appears proportional to (frequency × flux )^1.8^ . ]] || | || [[attachment:2605SA1_coreloss.jpg | {{attachment:2605SA1_coreloss.jpg}}]] || Core loss appears proportional to <<BR>><<BR>> (frequency × flux )^1.8^ .<<BR>><<BR>> Figure from datasheet. || |

Rotor Lamination

Laminated launch loop rotors will have good magnetic properties and will rapidly disperse and oxidize in the atmosphere after a rotor-release catastrophe. Worst case, thin flakes survive and cut.

Metglas 2605SA1 looks good, higher temperature than 2605HB1M. datasheet downloaded 2017/02/11

Metglas 2605SA1 |

||||

Curie temperature |

395C / 668K |

|

saturation induction |

1.56 Tesla |

thickness |

23 μm |

|

density |

7.18 g/cm³ |

Thermal Expansion |

7.6 ppm/°C |

|

Iron vaporization temp |

3140 K |

Tensile Strength |

1 GPa |

|

Elastic Modulus |

100 GPa |

Iron |

85 to 95% |

|

2.5g/m³ |

|

Silicon |

5 to 10% |

|

3.0g/m³ |

|

Boron |

1 to 5% |

|

2,0g/m³ |

|

resistivity |

1.3 μΩ-m |

|

|

|

60 Hz and 1.4 T |

|

Induction at 80 A/m |

≥1.35 T |

|

Core Loss |

≤0.17 W/kg |

|

Exciting Apparent Power* |

1.1 (VA/kg) |

Failure and oxidation

Iron has a specific heat of 25.1 J/(mol·K), vaporizes at 3140K, and has a heat of vaporization of 340 kJ/mol . Naively, to go from 400K to vaporization requires 410 kJ/mol or 16 MJ/kg . The rotor moves at 14 km/s, the kinetic energy is 98 MJ/kg, so there is more than enough energy to vaporize the rotor foil and ignite it. Further study and experimentation needed; perhaps most of the energy will end up in the surrounding air.