Rotor Lamination

Laminated launch loop rotors will have good magnetic properties and will rapidly disperse and oxidize in the atmosphere after a rotor-release catastrophe. Worst case, thin flakes survive and cut.

Metglas 2605SA1 looks good, higher temperature than 2605HB1M. datasheet downloaded 2017/02/11

Metglas 2605SA1 |

||||

Curie temperature |

395C / 668K |

|

saturation induction |

1.56 Tesla |

thickness |

23 μm |

|

density |

7.18 g/cm³ |

Thermal Expansion |

7.6 ppm/°C |

|

Iron vaporization temp |

3140 K |

Tensile Strength |

1 GPa |

|

Elastic Modulus |

100 GPa |

Iron |

85 to 95% |

|

2.5g/m³ |

|

Silicon |

5 to 10% |

|

3.0g/m³ |

|

Boron |

1 to 5% |

|

2,0g/m³ |

|

resistivity |

1.3 μΩ-m |

|

|

|

60 Hz and 1.4 T |

|

Induction at 80 A/m |

≥1.35 T |

|

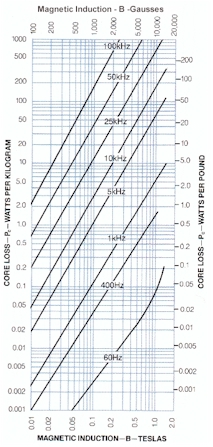

Core Loss |

≤0.17 W/kg |

|

Exciting Apparent Power* |

1.1 (VA/kg) |

Naively, assume that the rotor is excited at 100 KHz and produces 150 KN of thrust against a payload moving at a relative speed of 3 km/s with a wavelength of 0.1 m, an excitation frequency of 30 KHz. Assume a similar synchronous frequency (it will actually be slightly lower). Assume a sled length of 100 meters.

End of acceleration and track conditions |

||

payload speed |

11 km/s |

|

power |

1.65 GW |

extracted from rotor |

track coil pitch |

0.11 m |

|

track field frequency |

100 KHz |

|

rotor speed |

14 km/s |

|

rotor mass density |

3 kg/m |

|

rotor relative speed |

3 km/s |

|

rotor ΔV |

13.1 m/s |

Slowdown under sled |

rotor time under sled |

33.3 ms |

100m / 3000 m/s relative |

rotor acceleration under sled |

393 m/s² |

delta V / time |

rotor force per meter |

1179 N/m |

acceleration times mass density |

rotor total force |

117.9 KN |

the rest goes into the (rebounding?) track |

rotor coil pitch |

|

This varies along the track, longer at the end |

rotor field frequency |

low |

in rotor frame of reference |

Failure and oxidation

Iron has a specific heat of 25.1 J/(mol·K), vaporizes at 3140K, and has a heat of vaporization of 340 kJ/mol . Naively, to go from 400K to vaporization requires 410 kJ/mol or 16 MJ/kg . The rotor moves at 14 km/s, the kinetic energy is 98 MJ/kg, so there is more than enough energy to vaporize the rotor foil and ignite it. Further study and experimentation needed; perhaps most of the energy will end up heating the surrounding air, and the foil will fragment and fall to the ocean surface and then the sea floor.

Tape Wound Toroidal Transformers

http://www.butlerwinding.com/tape-wound-toroidal-transformer/

- 0.000125” = 3.175 μm

- available in alloys of silicon steel, nickel-iron, cobalt-iron, and amorphous metals