Tensile Truss

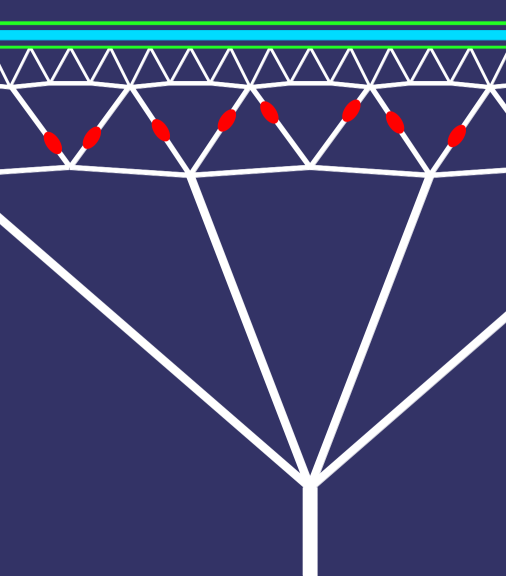

The following calculation is for a tensile cable form of a triangular truss, similar to a Warren truss, though we will use 63.4:63.4:53.2 degree triangles rather than equilateral triangles. That makes the wavelength of the truss equal the spacing - nothing magic about that, besides making the calculations a bit easier.

Simplified Vertical-Only Truss

Assume 28% of the support weight of the 80km 7kg/m track is devoted to tension on hanging pulldown cables to the surface, or 19 N/m of track. With an 80km support length, a 19 Newton cable weighs 0.24 g/m .

Assume that 5% of the weight the 7 kg/m launch track is devoted to the horizontal truss cables. If the cables are Kevlar, stressed to a support length of 80km, then the weight is 0.35 kg/m (cross section 2.4E-4 m2) and the tension is 280 kN. The curvature of this tension reduces the track lift by 4.4 g/m, one percent of the truss cable weight, negligible.

Assume that the truss is divided into a larger and smaller spreader section, the first with a wavelength and spacing of one meter, the second with a wavelength and spacing of 500 meters. Both sections pass the full force of the pulldown cables. Let's assume that 25% of the tension (70kN) is in the top lateral, 25% in the lateral 1 meter down, and 50% (140KN) is in the lateral 500 meters down.

The longitudinal speed of sound in Kevlar is 9.3 kilometers per second. The hypotenuse on 1 meter truss is 1.12 meters, so the speed of sound from the top to the bottom of that truss is 120 microseconds. The hypotenuse of the 500 meter truss is 60 milliseconds. We will hang moving actuators on the larger truss cables, as well as laser distance measuring transmitters at the joints.

The top stringers will weigh 0.5*1.25*0.24 g/m, or 0.15 grams per stringer. The lower stringers (both longer and more widely spaced) will weigh 5002 times that, or 100 kilograms each.

The bending moment of the top truss is E A W^2/2 , where W is the width of the truss. A = 6E-5 m2, W=1m, and E = 124 GPa, so the bending moment is 3.7E6 N/m2 for the top truss. The rotor stiffness is $ E 2.5E4 N/m2, so this section will stiffen the track/rotor system by 75X, increasing the minimum perturbation wavelength by the fourth root of that, or 3X. This will hold true down to time periods of 120 microseconds or so.

For the bottom truss, the area is doubled and the width is 500X, so A=1.2E-4, W=500m, and E= 124 GPa, resulting in a bending moment of 9.3E11 N/m2, 500,000 times stiffer than the first truss to large scale bending. That increases the minimum perturbation wavelength (compared to just the rotor) by 80x .

While stability is helpful, the main thing the lower truss does for us is increase the baseline for laser distance measurement.

MORE LATER

MORE LATER