|

Size: 2007

Comment:

|

Size: 2055

Comment:

|

| Deletions are marked like this. | Additions are marked like this. |

| Line 13: | Line 13: |

| If we lower the rotor speed to 12 km/s, that reduces ambit radius by a factor of 0.62 . That will require a more massive rotor (5 kg/m) for the same support force, but the iron portion can be wider so the ambit radius stays the same. Very high orbit payloads can be less massive and put less drag on a more massive rotor, though the delta V on the rotor from one 10.6 km/s, 5000 kg, 3 gee acceleration payload is only 20 m/s . | If we lower the rotor speed to 12 km/s, that reduces ambit radius by a factor of 0.62 . That will require a more massive rotor (5 kg/m) for the same support force, but the iron portion can be wider so the ambit radius stays the same. Very high orbit payloads can be less massive and put less drag on a more massive rotor, though the delta V on the rotor from one 10.6 km/s, 5000 kg, 3 gee acceleration payload is only 20 m/s. Delta is 14 m/s for the original 14 km/s rotor. |

New Rotor for Launchloop 2.0

|

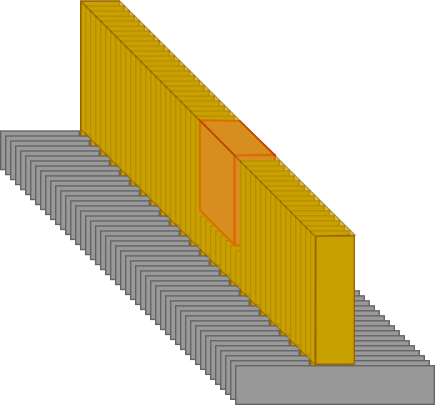

The new rotor will use a Kevlar-stiffened laminated transformer steel rotor and a vertical Kevlar bar with embedded permanent magnets. Kevlar is stronger and stretchier than iron or steel, so expansion joints are not needed to accomodate the stretch caused by the descent from 100 km altitude to the ground. The Kevlar backbone will provide enough stiffness to reduce "waviness", which allows for increased control circuit spacing for the ambit magnets. |

The Kevlar bar may be hollow with struts, with the magnets inside. All structures will be diamond/carbon coated to reduce spalling cascades.

The laminated metal crossbar can be deflected with magnets on the bottom, or a little less magnet from the top. The bottom will be turned sideways to face the inside "pivot" of the ambit magnets.

The magnets fly past aluminum coils, part of a high speed motor/generator system for the VelocityTransformer. The scale is on the order of 10 centimeters.

With transformer coupling, we need not run the rotor a lot faster than the vehicle; the relative speed is necessary only so the power extracted by the vehicle is not too high near exit speed. If the maximum launch speed is limited to Earth escape, about 10.7 km/s, that should be able to reach any Earth orbit, sending payload and passengers to interplanetary vehicle assembly orbits.

If we lower the rotor speed to 12 km/s, that reduces ambit radius by a factor of 0.62 . That will require a more massive rotor (5 kg/m) for the same support force, but the iron portion can be wider so the ambit radius stays the same. Very high orbit payloads can be less massive and put less drag on a more massive rotor, though the delta V on the rotor from one 10.6 km/s, 5000 kg, 3 gee acceleration payload is only 20 m/s. Delta is 14 m/s for the original 14 km/s rotor.