|

Size: 568

Comment:

|

Size: 543

Comment:

|

| Deletions are marked like this. | Additions are marked like this. |

| Line 3: | Line 3: |

| The new rotor will use a Kevlar-stiffened laminated transformer steel rotor and a vertical Kevlar bar with embedded permanent magnets. Kevlar is stronger and stretchier than iron or steel, so expansion joints are not needed to accomodate the stretch caused by the descent from 100 km altitude to the ground. The Kevlar backbone will provide enough stiffness to reduce "waviness", which allows for increased control circuit spacing for the ambit magnets. {{ attachment:rotor2.png }} {{ attachment:rotor2.svg }} |

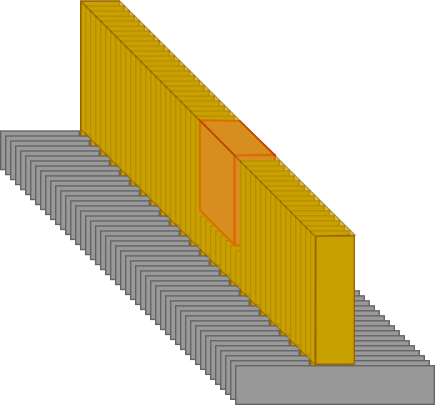

|| {{ attachment:rotor2.png }} || The new rotor will use a Kevlar-stiffened laminated transformer steel rotor and a vertical Kevlar bar with embedded permanent magnets. Kevlar is stronger and stretchier than iron or steel, so expansion joints are not needed to accomodate the stretch caused by the descent from 100 km altitude to the ground. The Kevlar backbone will provide enough stiffness to reduce "waviness", which allows for increased control circuit spacing for the ambit magnets. || |

New Rotor for Launchloop 2.0

|

The new rotor will use a Kevlar-stiffened laminated transformer steel rotor and a vertical Kevlar bar with embedded permanent magnets. Kevlar is stronger and stretchier than iron or steel, so expansion joints are not needed to accomodate the stretch caused by the descent from 100 km altitude to the ground. The Kevlar backbone will provide enough stiffness to reduce "waviness", which allows for increased control circuit spacing for the ambit magnets. |