|

Size: 6775

Comment:

|

Size: 11004

Comment:

|

| Deletions are marked like this. | Additions are marked like this. |

| Line 4: | Line 4: |

| The current reference space elevator design assumes solar-powered climbers. This assumes that vast areas of solar panels can cantilever from the sides of a climber - in gravity - and provide megawatts of climb power, while being lightweight and affordable. | Most of this page is obsolete and needs reworking. The semi-final paper I submitted is ''' [[attachment:ise2017.pdf|here]]'''. |

| Line 6: | Line 6: |

| .'''Solar cell self powered climbers are unlikely:''' The example pictured is a DLR solar sail (passive light pressure nanothrust), intended for microgravity, NOT an array of solar cells. Solar sails are ultrathin plastic films covered with just enough shiny metal to reflect light. Aluminum conductivity is 2.8e-8 ohm/meter; a film with 10 ohm per square resistivity (95% reflective) is 2.8e-9 meters thick - a few atomic layers. The density is 2700 kg per cubic meter, works out to 8 kilograms per square kilometer on top of the plastic. This is far less than actual satellite solar panels (300 W/m^2^, 1 kg/m^2^), which are designed for microgravity, not to deploy in a gravity field. These arrays are stabilized by gravitational gradients in orbit, and they are test-deployed on the ground hanging sideways from heavy structure. | The current reference space elevator design assumes solar-powered climbers. This assumes that vast areas of solar panels can cantilever from the sides of a climber - in gravity - and provide megawatts of climb power, while being lightweight and affordable. || {{ attachment:SolarSail-DLR-ESA.jpg | | width=300 }} || This is a solar SAIL, not a solar cell! <<BR>><<BR>> [[ attachment:SolarSail-DLR-ESA.jpg | bigger ]] from [[ http://www.lunarsail.com/wp-content/uploads/2013/05/SolarSail-DLR-ESA.jpg | here ]] and [[http://www.dlr.de/fa/Portaldata/17/Resources/dokumente/institut/2002/2002_04.pdf | here ]] and [[ http://www.esa.int/esapub/bulletin/bullet98/LEIPOLD.pdf | here ]]. || . [[ AcConduc | maximum conductance of 0.15 mS per carbon nanotube, doi:10.1002/adfm.201303716 ]] . [[ AcPhoto | A discussion of photovoltaics ]] .'''Solar cell self powered climbers are unlikely:''' The example pictured is a DLR solar sail (passive light pressure nanothrust), intended for microgravity, NOT an array of solar cells. Solar sails are ultrathin plastic films covered with just enough shiny metal to reflect light. Aluminum conductivity is 2.8e-8 ohm/meter; a film with 10 ohm per square resistivity (95% reflective) is 2.8e-9 meters thick - a few atomic layers. The density is 2700 kg per cubic meter, works out to 8 kilograms per square kilometer on top of the plastic. This is far less than actual satellite solar panels (300 W/m^2^, 1 kg/m^2^), which are designed for microgravity, not to deploy in a gravity field. Actual space solar arrays are stabilized by gravitational gradients in orbit, and they are test-deployed on the ground hanging sideways from heavy structure. |

| Line 9: | Line 16: |

[[ attachment:acoustic20150820c.pdf | A preliminary paper ]] |

|

| Line 15: | Line 20: |

| Click image for larger view or download [[attachment:ClimberPickoff.png | {{ attachment:ClimberPickoff.png | | height=400 }} ]] [[ attachment:ClimberPickoff.odg | !LibreOffice source ]] |

|

| Line 19: | Line 21: |

| A cheesy drawing of the two motor group "wheels". The grey "foot" makes contact to the tether when it passes by at maximum velocity. Alternating wheels have feet that turn in opposite directions, and the red and blue "free wheels" help maintain spacing but do not provide power. The power wheels turn at half the power vibration rate. | The actual wheels will be spring-loaded resonant wheels with magnets in them, twirling through a stator winding to produce power. Future drawings will be done with [[ http://povray.org/ | Povray ]], and include animations. |

| Line 21: | Line 26: |

Two counterrotating wheels will be paired in a small block; they will have shafts and bearings for low speed startup, but will transition to magnetic bearings (the magnets spin inside a semicircular stator) for high speed operation. Normally, the magnetic cam poles in a block on the north side of the tether will attract to cam poles in a matching block on the south side of the tether, pinching the tether. If blocks fail, they can be triggered to withdraw from tether contact; with perhaps 1000 little blocks, the loss of a few dozen during a climb will not impact performance. There will be two groups of motors for a climber, separated by 1/4 wavelength of acoustic vibration. The upper group will extract power from the vibration, launching electrical power and tension down to the lower group, which will reflect the vibrations back towards the top. The net effect will be like a quarter-wave radio antenna. A column of motor blocks should be able to briefly pop away from the tether, or adjust the strain they put on it, if high speed cameras above the upper group detect a flaw or anomaly in the tether. There will be plenty of error sensing, adaptability, and tether-protective behavior designed into the blocks and the whole climber motor system; climbers will arrive at the upper terminus with up-to-date tether maps as well as cargo. This will maximize tether durability and productive operating time between maintenance downtime, and facilitate rapid patching and repair during maintenance downtime. MoreLater -------- |

|

| Line 28: | Line 45: |

| WORK IN PROGRESS, not correct yet: ||<-2:> '''Electrical''' ||<-2:> '''Acoustic''' || ||<-4> Distance ( meters, m ) || ||<-4> Time ( seconds, s ) || ||<-4> Lumped parameters || || Energy (Joules, J) || ½·C·V² + ½·L·I² || Energy (Joules) || ½·kg·m²/s² = N·m || || Power (Watts, W) || V·A || Power (Watts) || kg·m²/s³ = N·m/s || || Current I (Amps, A) || mks fundamental unit || Displacement Velocity v || m/s || || Voltage V (Volts, V) || kg·m²/A·s³ || Force F (Newtons, N) || kg·m/s² || || Impedance R, Z ( Ohms, Ω ) || R = V/A = kg·m²/A²·s³ || Acoustic Impedance Z || kg/s || || Inductance L (Henries, H ) || L = Ω·s = kg⋅m²/A²·s² || mass m (kilograms, kg) || m || || Capacitance C (Farad, F) || C = s/Ω = s⁴⋅A²/m²·kg || compliance (1/spring) || m/N = s²/kg || ||<-4> Distributed parameters; X' ≡ linear derivative of X ≡ X per meter ; <X> ≡ average of X sin( ω T ) || || Energy/Length <J'> || ¼·C'·V²/m + ¼·L'·I² || Energy/Length <J'> || ¼·kg·m/s² = N || || Power/Length <W'> || V·A/m || Power/Length <W'> || kg·m/s³ = N/s || || Current I (Amps, A) || mks fundamental unit || Displacement Velocity v || m/s || || Voltage/Length V' || kg·m/A·s³ || Force F (Newtons, N) || kg·m/s² || || Impedance R, Z ( Ohms, Ω ) || R = V/A = kg·m²/A²·s³ || Acoustic Impedance Z || kg/s || || Inductance/Length || L' = kg⋅m²/A²·s² || mass/Length m' || kg/m || || Capacitance/Length || C' = s/Ω⋅m = s⁴⋅A²/m³·kg || compliance (1/spring) || m/N = s²/kg || |

|

| Line 29: | Line 68: |

| Line 35: | Line 73: |

| Line 39: | Line 77: |

| $~~~ L C ~ { \Large {{ \partial^2 I(x,t) } \over { \partial t^2 }} } ~=~ { \Large {{ \partial^2 I(x,t) } \over { \partial x^2 }} } ~~~~~ L C ~ { \Large {{ \partial^2 V(x,t) } \over { \partial t^2 }} } ~=~ { \Large {{ \partial^2 V(x,t) } \over { \partial x^2 }}} $ | $~~~ L C ~ { \Large {{ \partial^2 I(x,t) } \over { \partial t^2 }} } ~=~ { \Large {{ \partial^2 I(x,t) } \over { \partial x^2 }} } ~~~~~ L C ~ { \Large {{ \partial^2 V(x,t) } \over { \partial t^2 }} } ~=~ { \Large {{ \partial^2 V(x,t) } \over { \partial x^2 }}} $ |

| Line 49: | Line 87: |

| Sinusoidal solutions (many others are possible): $ ~~~I(x,t) = I_0 \sin( \omega t + k x )$ amps $ ~~~~~ V(x,t) = V_0 \sin( \omega t + k x )$ volts | Sinusoidal solutions (many others are possible): $ ~~~I(x,t) = I_0 \sin( \omega t + k x )$ amps $ ~~~~~ V(x,t) = V_0 \sin( \omega t + k x )$ volts |

| Line 53: | Line 91: |

| . speed $ ~ v ~ = ~ \omega / k ~ = ~ \pm 1 / \sqrt{ L C } ~ ~ $ in the +x or -x direction, a large fraction of the speed of light | . speed $ ~ v ~ = ~ \omega / k ~ = ~ \pm 1 / \sqrt{ L C } ~ ~ $ in the +x or -x direction, a large fraction of the speed of light |

| Line 65: | Line 103: |

| . $ e(x,t) $ strain of a cable element in meters at a specific distance $ x $ and time $ t $ | . $ \epsilon(x,t) $ strain of a cable element in meters at a specific distance $ x $ and time $ t $ |

| Line 74: | Line 112: |

| $ ~~~~~~~~ { \large e(x,t) = \Large {{ \partial \psi(x,t) } \over { \partial x }} } $ | $ ~~~~~~~~ { \large \epsilon(x,t) = \Large {{ \partial \psi(x,t) } \over { \partial x }} } $ |

| Line 76: | Line 114: |

| $ ~~~~~~~~ { \large f(x,t) = Y_c \Large { { \partial e(x,t) } \over { \partial x }} }~=~{ Y_c \Large {{ \partial^2 \psi(x,t) } \over { \partial x^2 }} } $ | $ ~~~~~~~~ { \large f(x,t) = Y_c \Large { { \partial \epsilon(x,t) } \over { \partial x }} }~=~{ Y_c \Large {{ \partial^2 \psi(x,t) } \over { \partial x^2 }} } $ |

| Line 84: | Line 122: |

| displacement: $~~{\Large{{\partial^2 \Psi(x,t)}\over{\partial t^2}} } = {\Large{Y_c \over \rho_c }~{{\partial^2 \Psi(x,t)}\over{\partial x^2 }} }~~~~$ velocity: $~~{\Large{{\partial^2 v(x,t)}\over{\partial t^2}} } = {\Large{Y_c \over \rho_c}~{{\partial^2 v(x,t)}\over{ \partial x^2}} }~~~~$ strain: $~~{\Large{{\partial^2 e(x,t)}\over{\partial t^2}} } = {\Large{Y_c \over \rho_c}~{{\partial^2 e(x,t)}\over{\partial x^2}} }$ | displacement: $~~{\Large{{\partial^2 \Psi(x,t)}\over{\partial t^2}} } = {\Large{Y_c \over \rho_c }~{{\partial^2 \Psi(x,t)}\over{\partial x^2 }} }~~~~$ velocity: $~~{\Large{{\partial^2 v(x,t)}\over{\partial t^2}} } = {\Large{Y_c \over \rho_c}~{{\partial^2 v(x,t)}\over{ \partial x^2}} }~~~~$ strain: $~~{\Large{{\partial^2 \epsilon(x,t)}\over{\partial t^2}} } = {\Large{Y_c \over \rho_c}~{{\partial^2 e(x,t)}\over{\partial x^2}} }$ |

| Line 88: | Line 126: |

| $ ~~~~~~~~ v(x,t) = v_0 \sin( \omega t + k x ) ~~~~~ $ and $ ~~~~~ e(x,t) = e_0 \sin( \omega t + k x ) $ | $ ~~~~~~~~ v(x,t) = v_0 \sin( \omega t + k x ) ~~~~~ $ and $ ~~~~~ \epsilon(x,t) = \epsilon_0 \sin( \omega t + k x ) $ |

| Line 90: | Line 128: |

| MoreLater, check the sign on $ e $ | MoreLater, check the sign on $ \epsilon $ |

| Line 92: | Line 130: |

----- |

------ |

Acoustic Climber for Space Elevator

Most of this page is obsolete and needs reworking. The semi-final paper I submitted is here.

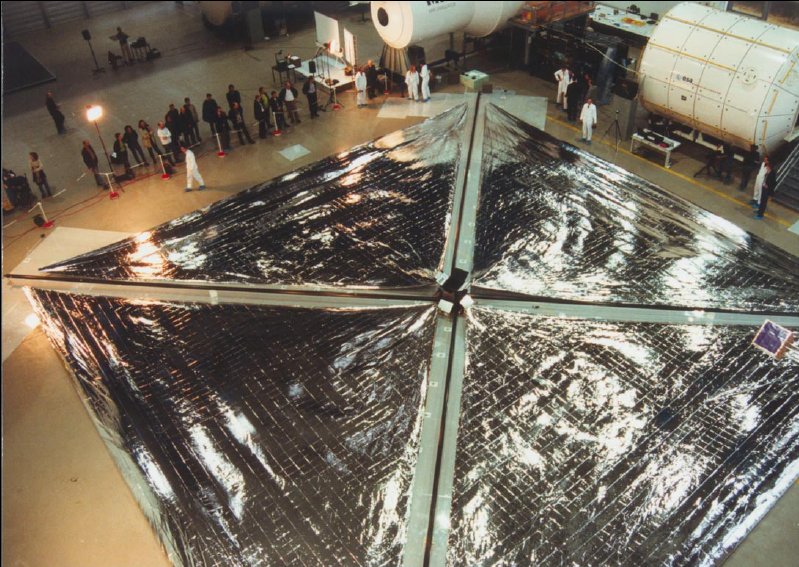

The current reference space elevator design assumes solar-powered climbers. This assumes that vast areas of solar panels can cantilever from the sides of a climber - in gravity - and provide megawatts of climb power, while being lightweight and affordable.

maximum conductance of 0.15 mS per carbon nanotube, doi:10.1002/adfm.201303716

Solar cell self powered climbers are unlikely: The example pictured is a DLR solar sail (passive light pressure nanothrust), intended for microgravity, NOT an array of solar cells. Solar sails are ultrathin plastic films covered with just enough shiny metal to reflect light. Aluminum conductivity is 2.8e-8 ohm/meter; a film with 10 ohm per square resistivity (95% reflective) is 2.8e-9 meters thick - a few atomic layers. The density is 2700 kg per cubic meter, works out to 8 kilograms per square kilometer on top of the plastic. This is far less than actual satellite solar panels (300 W/m2, 1 kg/m2), which are designed for microgravity, not to deploy in a gravity field. Actual space solar arrays are stabilized by gravitational gradients in orbit, and they are test-deployed on the ground hanging sideways from heavy structure.

Instead, a superstrong tether can carry megawatts of subkilohertz acoustic power, which can be impedance-matched and mechanically rectified (mad handwaving here) to produce climber thrust. The acoustic transmitters on the ground and at GEO node can provide 2 MW and 10 MW of climb power respectively, more by trading off climber mass, gravitational weight, and climber speed. Climbers will have a mechanical receiver that transforms vibration to rotary wheel motion.

That paper is old, a new one will be written with the material here. This is morphing into two banks of electrical motors separated by a quarter wave, with electrical power conversion at each motor group, and a power cable and stiff tether in between them.

The actual wheels will be spring-loaded resonant wheels with magnets in them, twirling through a stator winding to produce power. Future drawings will be done with Povray, and include animations.

Two counterrotating wheels will be paired in a small block; they will have shafts and bearings for low speed startup, but will transition to magnetic bearings (the magnets spin inside a semicircular stator) for high speed operation. Normally, the magnetic cam poles in a block on the north side of the tether will attract to cam poles in a matching block on the south side of the tether, pinching the tether.

If blocks fail, they can be triggered to withdraw from tether contact; with perhaps 1000 little blocks, the loss of a few dozen during a climb will not impact performance.

There will be two groups of motors for a climber, separated by 1/4 wavelength of acoustic vibration. The upper group will extract power from the vibration, launching electrical power and tension down to the lower group, which will reflect the vibrations back towards the top. The net effect will be like a quarter-wave radio antenna.

A column of motor blocks should be able to briefly pop away from the tether, or adjust the strain they put on it, if high speed cameras above the upper group detect a flaw or anomaly in the tether. There will be plenty of error sensing, adaptability, and tether-protective behavior designed into the blocks and the whole climber motor system; climbers will arrive at the upper terminus with up-to-date tether maps as well as cargo. This will maximize tether durability and productive operating time between maintenance downtime, and facilitate rapid patching and repair during maintenance downtime.

Analogy Between an Electronic Signal Cable and a Stiff Tether

All units MKS: meters, kilograms, seconds, volts, amperes (amps), radians

( FYI: if you don't think radians are a unit, you are turned around, and can't distinguish energy from torque. ![]() )

)

WORK IN PROGRESS, not correct yet:

Electrical |

Acoustic |

||

Distance ( meters, m ) |

|||

Time ( seconds, s ) |

|||

Lumped parameters |

|||

Energy (Joules, J) |

½·C·V² + ½·L·I² |

Energy (Joules) |

½·kg·m²/s² = N·m |

Power (Watts, W) |

V·A |

Power (Watts) |

kg·m²/s³ = N·m/s |

Current I (Amps, A) |

mks fundamental unit |

Displacement Velocity v |

m/s |

Voltage V (Volts, V) |

kg·m²/A·s³ |

Force F (Newtons, N) |

kg·m/s² |

Impedance R, Z ( Ohms, Ω ) |

R = V/A = kg·m²/A²·s³ |

Acoustic Impedance Z |

kg/s |

Inductance L (Henries, H ) |

L = Ω·s = kg⋅m²/A²·s² |

mass m (kilograms, kg) |

m |

Capacitance C (Farad, F) |

C = s/Ω = s⁴⋅A²/m²·kg |

compliance (1/spring) |

m/N = s²/kg |

Distributed parameters; X' ≡ linear derivative of X ≡ X per meter ; <X> ≡ average of X sin( ω T ) |

|||

Energy/Length <J'> |

¼·C'·V²/m + ¼·L'·I² |

Energy/Length <J'> |

¼·kg·m/s² = N |

Power/Length <W'> |

V·A/m |

Power/Length <W'> |

kg·m/s³ = N/s |

Current I (Amps, A) |

mks fundamental unit |

Displacement Velocity v |

m/s |

Voltage/Length V' |

kg·m/A·s³ |

Force F (Newtons, N) |

kg·m/s² |

Impedance R, Z ( Ohms, Ω ) |

R = V/A = kg·m²/A²·s³ |

Acoustic Impedance Z |

kg/s |

Inductance/Length |

L' = kg⋅m²/A²·s² |

mass/Length m' |

kg/m |

Capacitance/Length |

C' = s/Ω⋅m = s⁴⋅A²/m³·kg |

compliance (1/spring) |

m/N = s²/kg |

Electrical cable

Relationship between voltage and current in a uniform lossless electronic signal cable:

~~~~~~~~ { \Large {{ \partial V(x,t) } \over { \partial x }} } = - L { \Large { {\partial I(x,t) } \over { \partial t }} } ~~~~~~~~~~~ { \Large {{ \partial I(x,t) } \over { \partial x }} } = - C { \Large {{ \partial V(x,t) } \over { \partial t }} }

Wave equations for a uniform lossless electronic signal cable:

~~~ L C ~ { \Large {{ \partial^2 I(x,t) } \over { \partial t^2 }} } ~=~ { \Large {{ \partial^2 I(x,t) } \over { \partial x^2 }} } ~~~~~ L C ~ { \Large {{ \partial^2 V(x,t) } \over { \partial t^2 }} } ~=~ { \Large {{ \partial^2 V(x,t) } \over { \partial x^2 }}}

I(x,t) = current in amps at a specific distance x and time t

V(x,t) = voltage in volts at a specific distance x and time t

x = distance along cable in meters

t = time in seconds

C = capacitance per unit length, farads per meter

L = inductance per unit length, henrys per meter

Sinusoidal solutions (many others are possible): ~~~I(x,t) = I_0 \sin( \omega t + k x ) amps ~~~~~ V(x,t) = V_0 \sin( \omega t + k x ) volts

frequency ~ \omega ~ ~ radians per second

wavenumber ~ k ~ = ~ \pm \sqrt{ L C } ~ \omega ~ ~ radians per meter

speed ~ v ~ = ~ \omega / k ~ = ~ \pm 1 / \sqrt{ L C } ~ ~ in the +x or -x direction, a large fraction of the speed of light

a function of the materials used, typically around 0.5c or 150 million meters per second

impedance ~ Z ~ = ~ \sqrt{ L / C } ~ = ~ V_0 / I_0 ~ ~ ohms

- a function of the materials used and cross section, typically around 50 ohms but can be higher than 100 ohms and lower than 10 ohms

Mechanical cable

\Psi(x,t) displacement from rest of a cable element in meters at a specific distance x and time t

v(x,t) displacement velocity a cable element in meters at a specific distance x and time t

a(x,t) displacement acceleration a cable element in meters at a specific distance x and time t

\epsilon(x,t) strain of a cable element in meters at a specific distance x and time t

f(x,t) force on a cable element in meters at a specific distance x and time t

x = distance along cable in meters

t = time in seconds

Y_c cable spring constant, Newtons, Young's modulus Y times cross section A

\rho_c = \rho A cable density, kilograms per meter, density \rho times cross section A

Relationship between displacement, velocity, acceleration, tension, and strain in a mechanical cable:

~~~~~~~~ { \large \epsilon(x,t) = \Large {{ \partial \psi(x,t) } \over { \partial x }} }

~~~~~~~~ { \large f(x,t) = Y_c \Large { { \partial \epsilon(x,t) } \over { \partial x }} }~=~{ Y_c \Large {{ \partial^2 \psi(x,t) } \over { \partial x^2 }} }

~~~~~~~~ { \large v(x,t) = \Large {{ \partial \psi(x,t) } \over { \partial t }} }

~~~~~~~~ { \large a(x,t) = \Large {{ \partial^2 \psi(x,t) } \over { \partial t^2 }} }~=~{\LARGE{ 1 \over \rho_c }}~{\large f(x,t)} ~=~ { \Large { Y_c \over \rho_c } ~ {{ \partial^2 \psi(x,t) } \over { \partial x^2 }} }

Wave equations for a uniform lossless mechanical cable:

displacement: ~~{\Large{{\partial^2 \Psi(x,t)}\over{\partial t^2}} } = {\Large{Y_c \over \rho_c }~{{\partial^2 \Psi(x,t)}\over{\partial x^2 }} }~~~~ velocity: ~~{\Large{{\partial^2 v(x,t)}\over{\partial t^2}} } = {\Large{Y_c \over \rho_c}~{{\partial^2 v(x,t)}\over{ \partial x^2}} }~~~~ strain: ~~{\Large{{\partial^2 \epsilon(x,t)}\over{\partial t^2}} } = {\Large{Y_c \over \rho_c}~{{\partial^2 e(x,t)}\over{\partial x^2}} }

For sinusoidal waves,

~~~~~~~~ v(x,t) = v_0 \sin( \omega t + k x ) ~~~~~ and ~~~~~ \epsilon(x,t) = \epsilon_0 \sin( \omega t + k x )

MoreLater, check the sign on \epsilon